| A place for fun, learning, and exploration in the world of electricity and its technologies |

|

The Electronics of Model Trains Without a doubt one of my favorite toys when I was a kid was my electric train set. I can't recall what gauge it was, but it was about "Lionel" size, though not Lionel brand. For as much fun as it was though, there wasn't much that was realistic about it. This thing was all about raw horsepower, sparks, and the smell of ozone in the air. With a basic universal type (AC-DC) motor and simple rheostat controlled power supply you would have to use a lot of imagination to pretend you were driving the real thing. A slow, careful increase on the rheostat throttle would first make the motor hum and give off a faint smell of hot insulation. A little more and the wheels would start to jerk. "All aboard!" Finally the voltage would reach that magic threshold and she would shoot like a rocket, and if I was lucky it would even stay on the tracks! Unfortunately, today's model railroaders aren't able to experience this kind of excitement. Five-pole skew-wound motors, pulse-width modulating throttles, and DCC (digital command & control) systems have taken all the fun out of it. These electronic technologies have brought the hobby to such a level of realism that I fear what will become of our imaginations. :-) OK, now that I have that sarcasm out of my system I'll try to share with you what I think are really cool technologies that have evolved in a great hobby.

Lets start with the improvements towards mechanical realism. Unlike the electrical beast from my childhood, real-life trains don't start and stop so quickly and erratically. If you've ever watched a real freight or passenger train leave the station you noticed that it started with an almost imperceptible movement of the wheels and then accelerated very, very gradually. That's because of the tremendous inertia of the train. A typical modern diesel-electric locomotive has about 4,000 to 6,000 horsepower - that's a lot of pulling force! Often you will see multiple units coupled together to provide the needed locomotion for the specific load. But then you factor in that the load of cars being pulled is hundreds or thousands of tons in weight and you can understand why they accelerate and decelerate so slowly. Two technologies designed to mimic this behavior are five-pole skew-wound DC motors and pulsed DC modulating throttles with "momentum" breaking.

Inside the model locomotive is a small DC (direct current) motor.

Good quality units have a drive train that transfers the mechanical

power to all of the wheels that contact the track. Early models, and

Next, but no less important , is how you drive the motor. My train

set used a simple AC

Taking

realism a step further, additional technologies have been developed

to simulate the inertia and momentum of long, heavy train "consists"

(the specific locomotive and car makeup of a train). These systems

operate by automatically ramping-up or ramping-down the output in a

gradual way so that starting and stopping appears as it would with

the real thing. Also, there is a feature available called "Positive

Tracking Control". When a model locomotive pulls its cars up an

incline it will normally slow down from the increased mechanical

load. In the real world the train engineer would increase the

throttle to compensate for this, but with model railroading you may

not want to have to perform this duty each time an incline is

approached. Control designers figured out a way to do this

automatically by exploiting a DC motor characteristic called "back-EMF".

If you pick up a small DC motor and manually rotate its armature it

will act as a generator and output a voltage. With a moving model

locomotive this output, or back-EMF, can be detected by the

controller by momentarily interrupting its output and quickly taking

a measurement to determine approximate motor speed. If it senses the

motor slowing it can automatically increase its output to compensate

- just as a real engineer would! Pretty cool?

Now we move on to something the

computer science people can really sink their teeth into: DCC

(digital command & control). Fortunately for me the good people

at MRC provided an excellent primer on the subject, so I'll only

need to outline the basic features and benefits here. You can click

below to read the full primer.

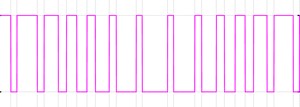

Digital Command & Control was initially developed to solve the

problem of operating multiple locomotives or trains on the same

section of track. You can understand how several different

locomotive motors driven off the same controller output simply

wouldn't work. You couldn't drive one without driving all of them,

and secondly, variations in motors and train sizes would cause some

to go faster than others, ultimately resulting in a collision

somewhere. With the evolution of digital electronic circuits a

system was developed where the track was powered by a steady AC sine

wave in which coded digital "packets" are imposed and then

recieved by their respective decoding devices. This allows the

use and operation of multiple trains - individually controlled - on

the same section of track. A mobile "decoder" is a device with a

specific digital address that controls aspects of a particular

moving train, such as speed, direction, and maybe some lighting. An

accessory decoder is typically used to control stationary items such

as building lights or track turn-outs. These systems continue to get

more sophisticated, and their uses are really only limited by your

own imagination! Click here to read more about DCC |

Home | About Us | Advertise | Submit an Article | Submit a Link | Contact Us

Copyright © electricalfun.com - All rights reserved